H piles are a cornerstone of deep foundation engineering, providing unmatched strength and support for heavy structures like bridges, towers, and commercial buildings. Their H-shaped cross-section offers high load-bearing capacity, and their ability to be driven deep into the ground makes them an essential tool in modern construction. But how exactly are they installed—and why are they so effective?

- 1. Site Preparation and Survey

- 2. Equipment Setup

- 3. Pile Driving

- 4. Splicing (If Required)

- 5. Pile Cutoff and Cap Installation

- Why H Piles Are Ideal for Foundation Stability

- Superior Load-Bearing Strength

- Efficient Ground Penetration

- Minimal Soil Displacement

- Long Lifespan

- Versatility

- Proven Track Record

- Conclusion

Here are the key steps in the installation process and the reasons why H piles are favored for foundational stability.

1. Site Preparation and Survey

Before installation begins, the site undergoes a thorough geotechnical survey. Engineers analyze:

- Soil composition

- Groundwater levels

- Load requirements

This data helps determine the required length, size, and spacing of H piles for optimal support.

2. Equipment Setup

Once the site is prepped, the installation equipment is brought in. This usually includes:

- A crane or rig to position the piles

- Hydraulic or diesel hammers for pile driving

- Vibratory drivers for specific soil types

The equipment is calibrated based on the size of the pile and the soil resistance encountered.

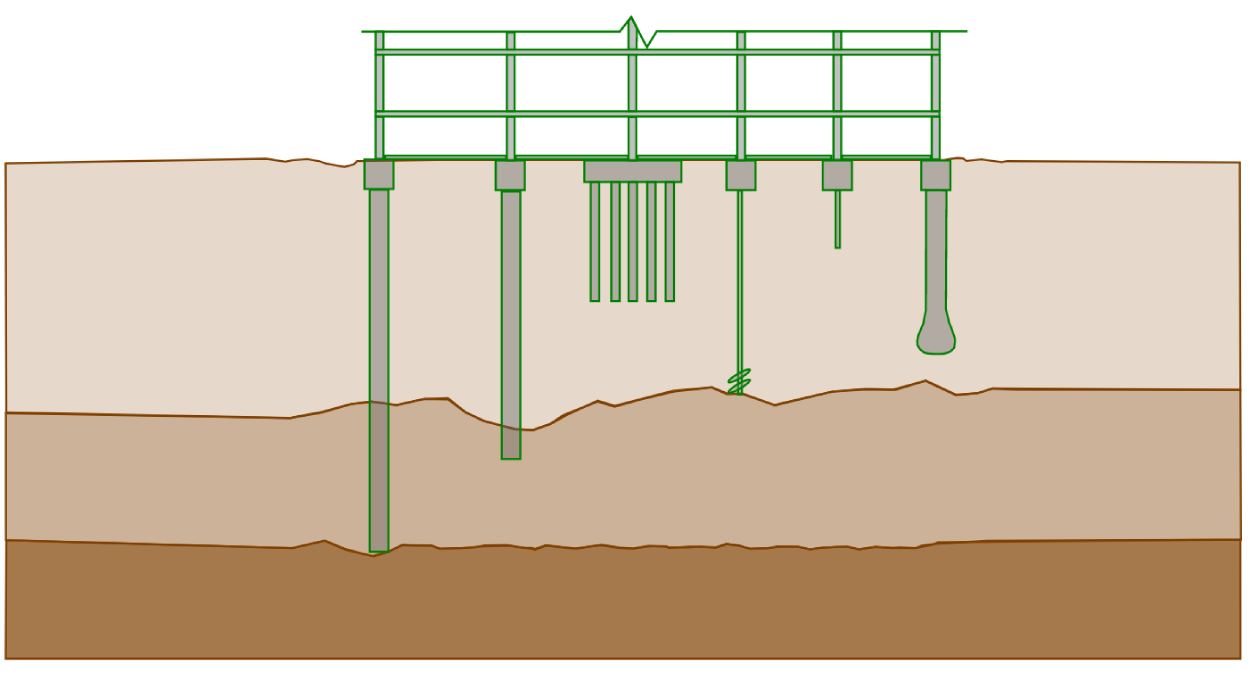

3. Pile Driving

The pile is positioned vertically and driven into the ground. During this stage:

- The steel H pile is repeatedly struck by the hammer

- Penetration continues until the pile reaches the load-bearing strata

- Driving is monitored using dynamic or static testing to confirm capacity

The shape of the H pile allows it to cut through tough soil layers and penetrate dense formations with minimal soil displacement.

4. Splicing (If Required)

For deeper foundations, piles may need to be extended mid-installation. This is done through:

- Welding or mechanical splicing

- On-site inspections to ensure structural continuity

Spliced piles continue to be driven until they meet required depth or resistance benchmarks.

5. Pile Cutoff and Cap Installation

Once all piles are in place:

- Excess pile length above the surface is cut off

- A concrete cap or steel grillage is installed to tie the piles together

- This cap distributes structural loads evenly across the pile group

The result is a robust support system ready for the above-ground structure.

Why H Piles Are Ideal for Foundation Stability

Superior Load-Bearing Strength

H piles are designed to support both axial and lateral loads, making them ideal for high-rise buildings, transportation infrastructure, and seismic zones.

Efficient Ground Penetration

Their slim, uniform cross-section allows them to penetrate deep into difficult soil conditions, including dense clays, sands, and even rock layers.

Minimal Soil Displacement

Unlike other pile types, H piles displace minimal soil during installation. This makes them ideal for urban sites where ground movement must be minimized.

Long Lifespan

With corrosion-resistant coatings and high-grade steel composition, H piles offer decades of reliable service in even the harshest environments.

Versatility

They can be installed in a variety of lengths and configurations and are suitable for both temporary and permanent structures.

Proven Track Record

Suppliers like Stealth Pipe & Steel provide certified, high-quality H piles engineered to meet stringent industry standards—ensuring performance and stability for every foundation application.

Conclusion

H piles are not only efficient to install but also provide one of the most reliable foundation solutions available in construction today. Their ability to handle extreme loads, adapt to challenging soils, and minimize site disruption makes them the go-to choice for engineers and builders. Understanding the installation process and advantages of H piles can help you make better decisions for your next structural project—building confidently from the ground up.